The assessment of environmental impact of materials is a crucial step in construction industry for sustainable development. Life Cycle Analysis (LCA) plays a major role in the selection of building materials based on their properties and their impact on environment. The LCA takes into account the materials’ environmental impact during all their life, ie. ‘from cradle to grave’, considering many basic parameters, such as the Gross Energy Requirement (GER), the Global Warming Potential (GWP), the Ozone Depletion Potential (ODP), the Acidification Potential (AP), etc. Unfortunately, this approach is rarely applied in the actual building design process due to its complexity, poor consensus on the weighing system and difficulty in quantifying all the mentioned parameters (Sandrolini, 2010).

The objective of this study is to quantify embodied energy, water consumption, waste category, temperature required in production, and solidification involved in cement mortar and ready-to-use slurry used for bonding of masonry material. The consumption of waste, waste generation, temperature and solidification of mix, etc., depends on properties of the ingredients and mix-design ratios. The embodied energy is defined as the energy consumed for the production of a material from the raw materials extraction and transportation, the manufacturing process and the transportation to the building site, up to the construction, demolition and recycling (Sandrolini, 2010).

Mortar

Mortars are bonding materials that integrate brick, clay or concrete into a masonry wall, binding the masonry units into a single element. Mortars are supposed to be strong, durable and capable of keeping the wall intact. Mortars also create a water-resistant barrier. The basic mortar ingredients include cement, hydrated lime, sand and water and it determines mortar type and performance.

Since the 1950s, the mineral binder within the mortar has gradually changed from lime to cement as a result of the easy availability of Portland cement. In order to improve the properties and performance, small quantity of liquid dispersion and plasticizer are also added to the mix. However, due to shortage of skillful workers and an increase in complexity of material applications, job-site mortar technology is not able to adequately meet the demand for achieving specific performance and consistent quality requirements (MIA, 2018).

Consequently, with the development and availability of new chemical additives in powdery form, the dry-mix mortar technology is invented to overcome the deficiency of the job-site mixed mortars. Factory premixed dry mortars ensure binders, fillers and chemical additives of known quality are blended exactly in desired ratio, thus ensuring a high degree of product performance and consistency (MIA, 2013), (MIA, 2018).

Ready-to-use mortar slurry – A case of build fast

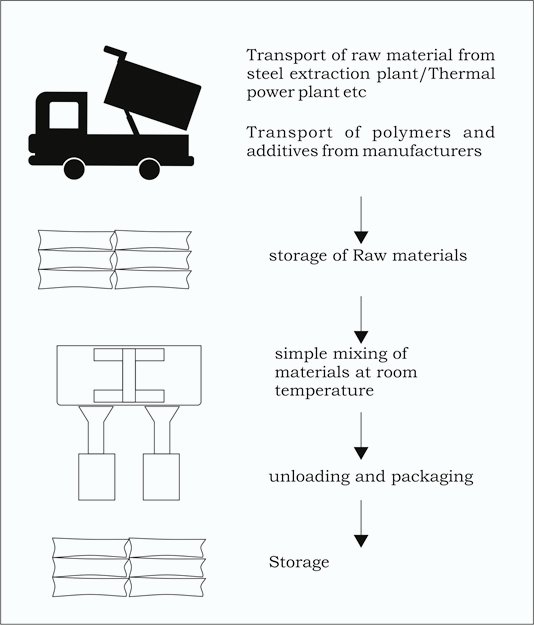

Build Fast is manufactured by simple mixing of fillers and binders such as fly ash/bottom ash, silica (quarry dust/recycled foundry silica), emulsified resin, additives such as pH stabilizers, coalescent, thickening agents etc., and water in a simple mixer at room temperature. The raw materials are essentially sourced from graded industrial wastes and mixed at room temperature with polymers and water and additives and no effluents are generated and no emissions are created during this process.

The product is a wet mix slurry /composite, which is unloaded by gravity in 25 kg and supplied in ready-to-use status for bonding masonry walls. The sealed material remains intact in bags for at least 120 days and, while using, the remaining material can be repacked and reused for further 15 to 20 days.

Comparison of Impact

In ready-to-use slurry, 70 to 80% ingredients used are industrial waste, which actually is redirected from landfills and used in production of wet slurry at factories. Table 1 shows the quantification of embodied energy, water consumption, waste category, temperature required in production and solidification for cement mortar and ready-to-use wet slurry, which helps in the comparative analysis for selection of material.

Table 3: Environmental impacts of Material mixes

| Sr. No. | Parameters | Unit | Cement mortar | Ready-to-use slurry | |

| 1 | Weight | Density of material | Kg/m³ | 2200′ | 1500″ |

| 2 | Embodied energy | Total consumption of energy from the extraction of raw materials until the finished product | MJ/Kg | 1.1′ | 4.74″ |

| 3 | Water consumption | Liters/Kg | 5 | 0.3 (consumed in product)” | |

| 4 | Waste category | Landfill | Landfill | Landfill | Recycled as raw material” |

| 5 | Temperature | Temperature requirement in production | °C | Portland Cement – 1400 – 1500* | Ambient temperature” |

| 6 | Solidification | Portland Cement – Reacts with water in a hydrating process | Fillers and binders react with each other due to increase in pH concentration when water evaporates and forms solid polymer matrix” | ||

The Embodied energy involved in material is seen higher for ready-to-use slurry mortar due to use of resin material which are the only virgin materials in the product. While, fillers that contribute to approximate 70% to 80% are not virgin materials but industrial by-product which is thrown away or, say, needs to be arrested in the interest of environment

The water used in ready-to-use slurry mortar production is consumed in slurry and there is no need to add water at the construction site before using the product. While in cement mortar, water and additives are added as per the requirements of design-mix proportion at the construction site. The water used for washing machinery in factory is recycled and used again in the process. So, overall consumption of potable water in the product is very minimal in one cycle of manufacturing process.

The production of ready-to-use slurry mortar is at ambient temperature, thus eliminating any heating/cooling activity and saving fuel. The cement mortar mostly goes to landfill at the end of life or after demolition. But, ready-to-use slurry mortar can be recycled completely and used as raw material in the next manufacturing process of product.

From this assessment and comparison of cement mortar and ready-to-use slurry mortar, it can be seen that wet slurry has less resource consumption and has more recycling properties. It helps to eliminate inaccurate site mixing, reduces labour and increases material efficiency with lower resource consumption and environmental impact.